|

|

TMS 2008: Continuing Education

You save when you register before February 11, 2008, for these short courses, tutorials and seminars.

| SHORT COURSE DESCRIPTIONS |

Grain Refinement of Aluminium Alloys: Theory and Practice

Short Course • Sunday, March 9 • 8 a.m. to 6 p.m.

Cost: $475 Members; $560 Nonmembers

Instructors

Paul Cooper, London and Scandinavian Metallurgical Co.

Douglas Granger, GRAS

Wolfgang Schneider, Hydro Aluminium GmbH

Peter Schumacher, University of Leoben

David St. John, Cast Metals Manufacturing

Who Should Attend

- Professional or technical representatives in the aluminium casting industry

- University researchers

Learn About

- Fundamentals of nucleation and grain growth

- Fundamentals of grain refinement with TiB2 and TiC

- Grain refiner alloys, grain refiner tests and grain size measurement

- Influence of grain refinement on product quality

- Practice of grain refinement in DC casting and shape casting

- Influence of casting conditions on grain refinement

About the Topic

Grain refinement is a melt treatment procedure to achieve an equiaxed grain structure of DC cast ingots and shape castings. An equiaxed grain structure facilitates fabrication and improves the yield of wrought products resp. improves the soundness of castings. To achieve an efficient grain refinement, knowledge about the grain refinement mechanisms, the different type of grain refiners, the grain refinement treatment process and the methods for the determination of the grain refinement result resp. the grain size is necessary.

Greenhouse Gas Emissions

Short Course • Sunday, March 9 • 9 a.m. to 3:30 p.m.

Cost: $475 Members; $560 Nonmembers

Instructors

Halvor Kvande, Hydro Aluminum

Jerry Marks, J. Marks & Associates

Alton Tabereaux, Consultant

Who Should Attend

- HSE professionals

- Aluminum industry operational employees

- Others wanting to learn more about greenhouse gas emissions and their reduction

About the Topic

Industry and rapid economic growth are major contributing factors to greenhouse gas emissions, global warming and climate change. Aluminum companies have realized that future profits, competitiveness and, ultimately, the long-term license to operate, will be based on ensuring the sustainability of finite natural resources. The aluminum industry is a part of the solution to climate change, and the good story about the progress already made needs to be communicated better.

The aim of this course is to highlight the environmental challenges facing the global aluminum business, both today and in the future, and to discuss how to reduce the greenhouse gas emissions from aluminum smelters. Anode effects in industrial electrolysis cells will be treated extensively, and the road ahead, with action plans and activities to minimize negative environmental impact and achieve a greener future, will be discussed.

Nanomechanical Characterization

Tutorial • Sunday, March 9 • 1 to 5 p.m.

Cost: $100 Members; $125 Nonmembers

Sponsored by TMS Materials Processing & Manufacturing Division

Instructors

Brad L. Boyce, Sandia National Laboratories

Erica T. Lilleodden, GKSS Research Center

Who Should Attend

- Scientists and engineers interested in mechanical behavior of materials at small scales, particularly nanoscale and nanostructured materials and micro and nanoscale devices

- Students, post-doctoral researchers, early career as well as senior scientists and engineers involved in academic research and industrial applications of thin films and nanomaterials subject to mechanical loads

About the Tutorial

Attendees will learn about the current state-of-the-art test methods as well as emerging methods in nanomechanical characterization through two lectures:

Nanoindentation-Based Techniques Nanoindentation-Based Techniques

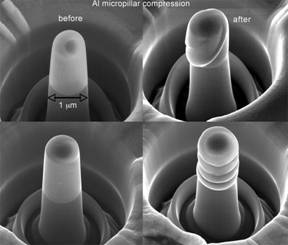

Nanoindentation-based test methods, ex situ as well as in situ indentation in a TEM, will be reviewed. The focus will be on issues unique to such small volume measurements, challenges and opportunities regarding sample preparation, and novel aspects of small-scale mechanical behavior (e.g., smaller is stronger both in indentation and micro-pillar compression testing). The theoretical approaches to understanding small volume deformation, current theories and the potential for testing these theories will also be discussed.

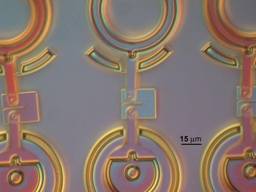

MEMS-Based Techniques

The mechanical characterization of micro and nanostructures often requires techniques based on microelectromechanical systems (MEMS). This brief overview of MEMS-enabled techniques will highlight key elements:

(a) microfabrication processes

(b) microfabrication materials

(c) mechanical actuator designs, i.e., electrostatic "comb" drives and thermal expansion actuators (c) mechanical actuator designs, i.e., electrostatic "comb" drives and thermal expansion actuators

(d) on- and off-chip force sensing schemes

(e) on- and off-chip displacement/strain sensing schemes

(f) implementation challenges including packaging and environmental control.

Several examples will be drawn from the literature and from work at Sandia National Laboratories, including methods for microtensile testing, fracture toughness, microtribology, delamination and fatigue. Recent advances in MEMS-based testing platforms for characterization of nanomaterials, including nanotubes and nanowires, will also be discussed.

Furnace Systems and Technology

Seminar • Monday, March 10-Wednesday, March 12 • 18 Sessions

| Presenting Companies |

|

|

| |

Air Liquide

Bloom Engineering

Dantherm Filtrations

Gillespie and Powers

Harbison Walker

|

Hauck Manufacturing

Maerz Gautschi

Mdy/Altek

Mechatherm International

Penta Engineering

|

Pyrotek/Emp Inc.

Seco/Warwick

The Schaefer Group

Thermcon – Otto Junkers

Thorpe Technologies |

Learn About

- Basic combustion, energy savings and improving furnace productivity

- Melting furnaces – style versus process, productivity, efficiency and design parameters

- Burners designs – cold air, preheated, regenerative and oxy/fuel

- Emissions and abatement – NOx, CO, particulate and dioxin

- Recirculating process furnaces – design, purpose, production and efficiency

- Metal circulation, cleaning and dross processing

- Casting – type of casters and applicability

- Refractory issues and practices

- Contract engineering – when does it make sense?

Cost: $200 members; $250 nonmembers / includes seminar and admittance to exhibition

| FOR MORE INFORMATION . . . |

For additional information regarding this meeting, please complete the TMS Meetings Mailing List Form or contact:

TMS

Meeting Services

184 Thorn Hill Road

Warrendale, PA 15086 USA

Tel: (724) 776-9000 x243

Fax: (724) 776-3770

Email: mtgserv@tms.org

|