|

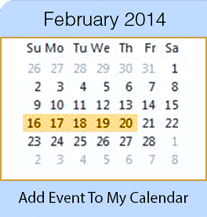

| Date: | Tuesday, February 18, 2014, 8:30am - 12:20pm |

| Organized by: | Charles Ward, Air Force Research Laboratory and Hani Henein, University of Alberta and Sponsored by the TMS Materials Innovation Committee |

| Sponsored by: | TMS Materials Innovation Committee |

Combining recent emphases on manufacturing advances and acceleration of materials innovations, this special keynote session will focus on the current state of the art and future international landscape of integrated materials and manufacturing innovations. In particular, it will examine regional perspectives from leading government organizations around the world. Esteemed speakers will present overviews of their current activity areas, as well as previews of what is on the horizon for materials science and engineering innovations, especially as they relate to manufacturing.

|

JIAN-FENG NIE

Professor of Monash University in Australia

Title: "Materials and Manufacturing Innovations: An Australian Perspective"

Abstract: Melbourne Clayton hosts Monash University and CSIRO Division of Materials Science and Engineering, in addition to several other CSIRO divisions, the Australian Synchrotron and the Melbourne Nanofabrication Centre. Recently, a $180m New Horizons building was constructed adjacent to Monash Engineering and CSIRO MSE that can accommodate 450 people to conduct research in a collaborative way. This talk will look at issues that are conducted at these two institutions and that are critically important to Australia: from efficient energy usage, effective water management and wastewater treatment, textile technology for tissue growth and medical imaging, to cold spray technology that is changing the coating industry. This talk will also look at the severe plastic deformation processes that have attracted considerable attention in the past many years for fundamental study.

Bio: Dr. Jian-Feng Nie is a professor of Monash University in Australia. He has been working

on physical metallurgy for the past 20 years. He graduated from Monash University in 1993,

and did his postdoc in the University of Queensland and former CSIRO Division of Materials

Science and Technology from 1993 to 1995. He returned to Monash University in 1995 and has

been working at Monash since then. Professor Nie has been working on physical metallurgy,

phase transformations, and microstructural characterisation. He is a member of TMS,

former chair of the Phase Transformations Committee of TMS, chair of the Events Committee

of Materials Australia, and editor of Metallurgical and Materials Transactions since 2013. Dr. Foley is well known for her interests in physics, science education, women in science, science in the media (she was a regular weekly guest on ABC radio 2BL radio for 5 years) and nuclear disarmament. She was awarded a Public Service Medal on the 2003 Australia Day, won the 2003 Eureka Prize for the promotion of Science and the NSW and National winner of the Telstra Women’s Business Award for Innovation in 2009, the AUSIMM MIOTA Prize in 2011, and the 2-13 NSW Premier’s Women of the year.

|

|

HAN DONG

Vice President of Central Iron & Steel Research Institute, and director of National Engineering Research Center of Advanced Steel Technology

Title: "Innovations form Bridging Materials Production and Component Manufacture

Central Iron & Steel Research Institute, Beijing, China

Abstract: The Chinese government is seeking to form the new strategic industry induced by the developments of new materials and high performance alloys. Alliances among materials production, component manufacture and academy are encouraged to guarantee the applications of materials researched. In the transportation area, high strength steel sheets are developed to reduce the car weight with the ductility improvement to meet the stamping requirement. And hot forgings in the engine and chassis are tailored to optimize the steel property and component performance. Long steel rail and relative construction technologies are the rail road basis for high speed train over 10,000 km. X80 steel pipeline has been in the operation in the west to east lines for crude oil transportation. These are typical cases of integrated cooperation of materials production and component manufacture. More attentions have been paid on processing parameters of production and manufacture on the vitality of materials developed.

Bio: Dr. Han Dong, vice president of Central Iron & Steel Research Institute, and director of National Engineering Research Center of Advanced Steel Technology. He has been working in the steel field since 1988, and mainly involved in the research on advanced steel technology, specifically on microalloyed steel, automotive steels, high nitrogen stainless steel and ultra-high strength steel. Dr. Dong is now the chief scientist of a National Basic Research Program of China (973 Program): On the Performance Improvement of Steels through M3 Structure Control (2010-2014). He has published 190 papers and has been granted 17 Chinese patents in the steel area.

|

|

DR. G. SUNDARARAJAN

Director, International Advanced Research Centre for Powder Metallurgy and New Materials, Hyderabad & Professor, Indian Institute of Technology Madras, India

Title: "Status of Advanced Manufacturing: Indian Perspective"

Abstract: The Indian manufacturing industry is a study in contrast. On one side, India has been ranked as second in the world (next only to China) as per Global Manufacturing Competitiveness Index (GMCI) and is second only to Japan in the number of manufacturing companies awarded quality of excellence (like Deming and TPC Excellence Awards). In addition, India has made a world-wide impact through its innovative concepts on lean/frugal manufacturing. On the other side, manufacturing in India accounts only 16% of the GDP and has stagnated at that level during the last decade. Indian exports of manufactured goods were around USD 170 billion in FY 2011 and this represents only 2.2% of the world total. Thus, Indian manufacturing industry is at cross-roads and needs to enhance its manufacture base. To meet these challenges, the Indian Government has introduced the National Manufacturing Policy in the year 2011. This policy has a number of innovative features which will be described. Concomitantly, the field of manufacturing itself is undergoing dramatic changes not only in terms of the advent of new advanced manufacturing technologies but also in terms of new types of products/goods being manufactured in large scale like the Li-ion battery for electric vehicles, solar panels of various types, fuel cells, wind mill components etc. All these aspects, from the Indian perspective, will be discussed.

Bio: Dr.G.Sundararajan, obtained his B.Tech (Metallurgy) from Indian Institute of Technology, Madras in 1976 and M.S and Ph.D from Ohio State University, Columbus, Ohio, U.S.A in 1979 and 1981 respectively. He returned to India in September 1982 and joined Defence Metallurgical Research Laboratory (DMRL) as a scientist. He was at DMRL till 1997 and then was appointed as Director of International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), Hyderabad from September 1997. From February 2013, Dr. Sundararajan holds joint appointment as Professor at Dept. of Metallurgical & Materials Engg., Indian Institute of Technology, Chennai.

During the course of his research career at DMRL and ARCI, Dr. Sundararajan has made outstanding contributions to the areas of tribological behavior of metallic materials, composites and coatings, high temperature deformation and fracture behaviour of superalloys and other materials, laser surface modification (surface alloying cladding, transformation hardening) and laser materials processing (cutting, drilling & welding) of engineering materials. He has also made substantial contributions towards the development of novel coating technologies like detonation spray coating, electro spark coating, microarc oxidation coating, cold spray coating and EB-PVD coating technologies. At ARCI, as its Director, Dr. Sundararajan had made notable contributions to the development, demonstration and commercialization of materials-based technologies. Over the last 10 years, over 35 technologies have been transferred to private industries located all over India.

Dr. Sundararajan is a Fellow of the American Society for Materials (2005) and The American Ceramic Society (2012). He is also a Fellow of the Indian Academy of Sciences (1992), Indian National Science Academy (1996) and the Indian National Academy of Engineering (1999). He has published more than 230 papers in refereed international journals and peer-reviewed conference proceedings and has guided the Ph.D work of many of his colleagues at DMRL and ARCI. He is currently the Vice President of the Indian Academy of Sciences and also the President of Materials Research Society of India.

|

|

DR. YOSHIO AKIMUNE

General Manager, Technical Planning Division, Innovative Structural Materials Association, Japan

Title: "Introduction to the new project named 'Innovative Advanced Structural Materials'"

Abstract

Drastically reduce weight (by half) of transportation equipment, primarily automobiles; promote the development of the innovative material joining technologies required to properly use newly developed materials in the right application, and develop technologies for enhancing the strength of major structural materials such as iron and steel, non-ferrous, and carbon-fiber-reinforced plastic(CFRP) materials for use in transport equipment.

In order to solve these issues, Japanese Ministry of economy trade and Industry (METI) proceeds the new research project named "Development of innovative structural materials." This project aims to develop high-performance materials, such as titanium alloy, CFRP and innovative steel sheet, which can improve multiple functions at once, including strength, ductility, toughness, seismic control capability, corrosion resistance, and impact resistance, and develop technologies for joining different materials, with a focus on applications to transportation equipment for which weight reduction is required. These technologies are intended to enhance the most out of the properties of various materials, thereby significantly improving the fuel efficiency of the transportation equipment through weight reduction.

Bio: My personal history:

March 1976 ME, Applied Chemistry, Waseda University

August 1985 MS, Ceramic Science and Engineering, University of Washington

- Advisor:Dr. Richard C. Bradt (now University of Alabama)

August 1990 Doctor of Engineering, the Tokyo University

- Advisor: Dr. Teruo Kishi

Job Experience

1976-1999 Nissan Motor Co., Ltd. Nissan Research Center

Development of Ceramic Turbocharger Rotor

Synergy Ceramic Project (Development of Heat Conductive Silicon Nitride

1999-2011, Director of Research Strategy

National Institute for Advanced Interdisciplinary Research,

AIST, Ministry of International Trade and industry

Deputy- Director of Smart Structure Research Center

Director of Research Institute of Instrumentation Frontier

2011 - 2013 Supervisory Innovation Coordinator Tsukuba Innovation Arena

2013 - Innovative Structural Materials Association

Research Field

Research and Development of Inorganic Functional/Structural Materials

Application Technique of ceramics to automotive components

Awards

* Nikkei BP Award for Silicon Nitride Insitu-Composite (1993)

* Gold award in Academic Photographic Contest of Japan Ceramic Society (1999)

|

|

DR. LAURIE LOCASCIO

Director, Material Measurement Laboratory, The National Institute of Standards and Technology (NIST), USA

Title: "The Materials Genome Initiative: Materials from Discovery through Manufacturing"

Abstract:

The Obama Administration's Materials Genome Initiative seeks to dramatically reduce the time and cost to develop new materials for use in manufactured products. To achieve these ends, the Federal Agencies have been developing strategies to create the materials innovation infrastructure that lies at the heart of the Materials Genome Initiative. The White House Office of Science and Technology Policy has led a coordinated effort to define the key roadblocks, critical investments, and policy shifts that can bring about this paradigm shift in how materials research is conducted. In support of this effort, NIST has embarked on a program, in concert with its partners in industry, academia and government, to develop the tools, standards and techniques for (1) the essential data and model exchange protocols and the (2) means to ensure the quality of materials data and models, ultimately (3) yielding new methods, metrologies, and capabilities necessary for accelerated materials development.

Bio:

Dr. Laurie E. Locascio is the director of the Material Measurement Laboratory at the National Institute of Standards and Technology. The Material Measurement Lab has more than 900 staff members and visiting scientists, and serves as the nation's reference laboratory for measurements in the chemical, biological and materials sciences through activities ranging from fundamental research in the composition, structure, and properties of industrial, biological, and environmental materials and processes, to the development and dissemination of certified reference materials, critically evaluated data, and other measurement quality assurance programs. The Material Measurement Laboratory serves a broad range of industry sectors ranging from transportation to biotechnology, and provides research, measurement services, and quality assurance tools for addressing problems of national importance ranging from assessment of climate change, to the investigation of new sources of renewable energy, to improved diagnostics and therapies for health care.

Dr. Locascio received her B.Sc. in chemistry from James Madison University, M.Sc. in bioengineering from the University of Utah, and Ph.D. in toxicology from the University of Maryland School of Medicine. She has published more than 100 scientific papers and holds eight patents in the fields of microfluidics, biosensors and sensor/flow systems. Some of her honors and awards include the U.S. Department of Commerce Silver Medal, U.S. Department of Commerce Bronze Medal Award, ACS Division of Analytical Chemistry Arthur F. Findeis Award, the NIST Applied Research Award, and is a Fellow of the American Chemical Society (ACS). Dr. Locascio serves as co-chair of the National Science and Technology Council MGI Subcommittee that resides under the Committee on Technology.

|

|