TMS 2016 Course Offerings

12th Annual Lead-Free Solders and Interconnect Technology Workshop

Additive Manufacturing Materials and Processes Workshop

Avizo 3D Analysis Software for Materials Science*

Characterization of Dielectric Materials for Microwave Processing

Effects and Control of Impurities Along the Aluminum Value Chain

Energy Management in the Materials Industry

Explore CES Software Tools for Materials Related Critical Decision-Making in Industry, Research, and Education*

Managing Technical and Financial Risk in a New Technology Project Environment

Multiphysics Materials Simulations Using the Open Source MOOSE Framework

NSF Grant Proposal Writing Workshop

Practical Methods for "In-Plant" Testing of Carbon Anodes Used in Aluminum Smelting

|

This course has been cancelled for TMS2016.

| Title | Managing Technical and Financial Risk in a New Technology Project Environment |

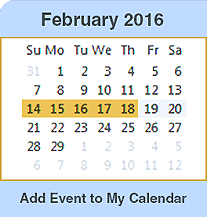

| When | Sunday, February 14, 2016, 8:30 a.m. to 4:30 p.m. (CST) |

| Where | Music City Center |

| Sponsorship | TMS Extraction & Processing Division (EPD), Pyrometallurgy Committee, and Professional Development Committee |

| Presenters | Phillip J. Mackey, P.J. Mackey Technology Inc.; Mark W. Kennedy, ProVal Partners SA and Norwegian University of Science and Technology; and Carmine Ciriello, Analyze and Improve |

| Workshop Length | Full day |

| Flyer |

View / Download View / Download |

"Instructors provided excellent explanation of framework for phase field and finite elements. Very empowering course."

—TMS2015 Course Attendee

SCOPE

Course Objectives:

- Review the past performance of major mining and metallurgical projects.

- Identify the root causes of risk in mining and metallurgical projects, and particularly those with a high component of new technologies.

- Review standard project management techniques and introduce specific methods to identify and manage risks in new technology projects.

- Ensure that the course participants are familiar with standard financial analysis methods for projects.

- Introduce new mathematical methods to asses financial risk in new technology projects, whereby marginal projects can be prevented from proceeding, while sound projects can be given the additional time and resources required to achieve the optimal level of front-end-loading (the level which returns the maximum rNPV).

- Enable the course participants to take back to their work place, a set of mathematical tools that will allow both engineers and financial professionals to establish a common level of understanding on risk, thereby leading to more accurate assessment of projects, better decision making and enhanced project financial returns.

Participants will:

- Review previous mega-project mining and metallurgical early plant performance.

- Learn the sources and types of technical and technological risks in mining and metallurgy projects.

- Review common project and risk management tools (front-end loading, staged project management, risk analysis, risk registers, mitigation strategies, hazard identification studies, HAZOP and FMECA, Monte Carlo, Six Sigma, and design for Six Sigma).

- Explore systematic methods of quantifying and controlling project risk in new technology projects for a more successful outcome (technology risk reviews, design and scale-up methods—DMAIC, project execution strategies, project scheduling, flow sheet modifications, and safety).

- Review standard methods for the financial analysis of projects.

- Learn new methods of assessing the financial impact of technical and technological risk, in the form of risk-weighted cash flow and risk weighted net present value (rNPV).

WHO ATTENDS?

Managers, financial professionals, engineers, and support staff working with large and small capital projects and particularly those incorporating new technology will benefit from attending this workshop.

TOPICAL OUTLINE

Topics for this course will include:

- Start-up and early performance of new mining and metallurgical projects: A case study analysis

- Technical and technology risks impacting mining and metallurgical project performance

- Project management tools part I: a quick review of risk registers, risk assessment, mitigation, HAZAOP, FMECA, front-end-loading (FEL), and staged project management systems

- Project management tools part II: Six Sigma, design for Six Sigma and Monte Carlo simulation in a new technology environment

- Special methods to identify and control risks in a new technology environment: technology risk reviews, design and scale-up methods—DMAIC, project execution strategies, project scheduling, flow sheet modifications, and safety

- Basic project financial analysis tools: how to calculate internal rate of return (IRR), discounted cash flow (DCF), and net present value (NPV) of a project?

- Introduction to the theory for risk weighted DCF and rNPV

Practical group assignments for this workshop will include:

- Risk identification and staged mitigation strategies.

- Overall Assessment of project risk using the new mathematical and decision making techniques.

INSTRUCTORS

Phillip J. Mackey

Phillip J. Mackey is president of P.J. Mackey Technology Inc. and is involved in consulting on metallurgical projects worldwide after many years associated with Noranda/Falconbridge and Xstrata working in all areas of nonferrous metallurgy. He has over 40 years of broad, in-depth experience and understanding of the nonferrous metals business including operations (including start-up of new plants) and technology, in particular for nickel, copper, and precious metals. He has authored or co-authored over 100 publications covering many aspects of nonferrous metallurgy, including commissioning new plants and metallurgical history. Mackey played a leading role in the development of the Noranda Process, the world’s first commercial continuous copper smelting and converting process and one of the important copper technologies developed in the twentieth century. He is a licensed professional engineer in Canada and served as president of The Metallurgical Society (MetSoc) of the Canadian Institute of Mining, Metallurgy, and Petroleum (CIM) from 1983 to 1985. He is also a Fellow of both the CIM and TMS.

Mark W. Kennedy

Mark W. Kennedy is a licensed professional engineer in Ontario and has worked on major capital projects through every project phase from invention, lab, pilot, demonstration, and feasibility through basic, value and detailed engineering, construction, start-up, ramp-up, and operations. This gives him an excellent perspective on new technology and its impact on project engineering. He is currently a partner in ProVal Partners SA of Lausanne, Switzerland and a postdoctoral fellow at the Norwegian University of Science and Technology in Trondheim, Norway. ProVal Partners provides advisory services to the nonferrous metal industry. Has more than 20 years in the metallurgical industry (nickel, ferro-nickel, zinc, copper, magnesium, aluminum, and materials) in plant operations, project engineering, and applied research.

Carmine Ciriello

Carmine Ciriello is a managing partner at Analyze and Improve, with focus on operational improvement and management systems. Ciriello holds bachelor’s and master’s degrees in metallurgical engineering from McGill University, is a registered professional engineer of Ontario, and a Lean Six Sigma Master Black Belt. He has authored or co-authored several publications, and delivered numerous courses in the areas of operational improvement, including the application of Lean Six Sigma within project management. He has over 20 years of operational, continuous improvement, corporate, technical, and research experience within the mining and metallurgical industries.

INSTRUCTOR TESTIMONIAL

The natural outcome of new technology mega-projects seems to be a technological success, but a financial failure. All those who have failed before us were just as intelligent, educated, and experienced as we are. The best way to avoid sharing their fate is to study their modes of failure and improve our project management systems accordingly.

Mega-projects are so vast that no single human mind can encompass their complexity or predict the interactions between all the parts. The only way to successfully manage such projects is through systems (e.g., change management, HAZOP, technology risk reviews) and lists (e.g., risk registers). Not only must we engage creative, intelligent, and experienced people and forge integrated multi-disciplinary teams to be successful with large-scale new technology projects, but we must also give them the time, resources, and systems they require to be successful.

Success at mega-projects and particularly those involving new technology involve extensive front-end loading (FEL) and careful systematic development and execution.

-Mark W. Kennedy

REGISTRATION

Registration Fees*:

Before January 8, 2016

After January 8, 2016

* Registration fees include lunch.

** Must be a full-time student at an accredited university to register at the student rate. Copy of valid student school identification card must accompany registration form.

Please note that presentations may contain commercial content.

|

| BACK TO COURSE LISTING |

|