TMS 2017 Course Offerings

Full Day Events

Emerging Electronic Interconnect Materials and Processing for Advanced Packaging Technology Workshop

Refractory Linings Used in Aluminum Production

Half-Day Morning Events

Hands On: Interactive Materials Data Visualization and Selection Tools for Research and Teaching Workshop

Hands On: New Demos and Activities to Engage Students in Materials Science and Engineering Workshop

Managing Sulfur in Cokes, Anodes, and Smelter Potline Exhaust Gases Course

Half-Day Afternoon Events

Additive Manufacturing Materials and Processes Workshop

Emerging Technologies that are Poised to Change the Aluminum Industry Workshop

How Carbon Materials are Used in Aluminum Production Workshop—an Introduction for Non-Technologists

Introduction to Atom Probe Tomography Workshop

|

| Refractory Linings used in Aluminum Production Workshop |

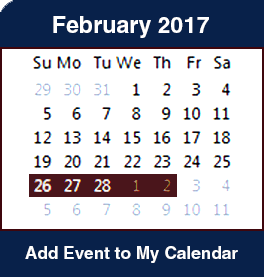

| When | Sunday, February 26, 2017 • 8:30 a.m. to 4:30 p.m. |

| Where | San Diego Convention Center |

| Sponsorship | TMS Light Metals Division (LMD) and Aluminum Committee |

| Instructors | Johan Arnold Johansen, Elkem Carbon AS; Tor Grande, Norwegian University of Science and Engineering; Eirik Hagen, Hydro Aluminium; Christian Schøning, SINTEF Materials and Chemistry; Egil Skybakmoen, SINTEF Materials and Chemistry; Asbjørn Solheim, SINTEF Materials and Chemistry; and Zhaohui Wang, SINTEF Materials and Chemistry |

| Flyer |

View / Download View / Download |

SCOPE

The physical properties and the behavior of the refractory linings used in aluminum electrolysis cells and in anode baking furnaces are crucial for economic as well as environmental aspects of the aluminum production. This course will give an introduction to the physical and thermal properties of materials used in the industry, covering the different type of carbon cathode materials, refractories, and thermal insulating lining materials used in the aluminum industry. Chemical reactions causing the most important degradation mechanisms for the different materials will be covered, with focus on the lifetime of the pot lining and heat balance of the cells. Finally, industrial experiences with lining materials will be included.

WHO ATTENDS?

The course will benefit smelter operators, process and cell design engineers, suppliers of refractories, researchers and students whose work relates to aluminum reduction technology and refractory materials science.

TOPICAL OUTLINE

- Introduction to refractory materials

- Refractories in anode baking furnaces

- Barrier bricks in aluminum electrolysis cells

- Insulation materials in aluminum electrolysis cells

- Carbon cathodes

- Nitride bonded silicon carbide sidelining materials

- Degradation mechanisms

- Conditions and reaction paths in the bottom lining

- Industrial experiences

INSTRUCTORS

Johan Arnold Johansen

Johan Arnold Johansen is senior specialist carbon & graphite materials in Elkem Carbon AS located in Norway. He has more than 40 years of experience from aluminum production, cathode design and development of carbon materials for different applications in the metallurgical industry. He has participated in several research projects involving universities, institutes, and industry on topics related to carbon materials in cathodes. He holds several patents related to production of carbon materials for different applications.

Tor Grande

Tor Grande is a professor in materials science and engineering at the Norwegian University of Science and Engineering (NTNU). He is currently also the vice dean in research and innovation at the Faculty of Natural Science and Engineering at NTNU. He received a Ph.D. in inorganic chemistry from the Norwegian Institute of Technology (NTH) in 1992. He became an associate professor at NTH after postdoctoral research at Arizona State University and he has been a professor at NTNU since 1997. He has been on sabbatical leave at Northwestern University and EPFL in Switzerland. His research interests covers a wide range of topics in materials science and engineering from the synthesis and properties of ceramic materials, thermodynamics of materials and refractory and carbon materials for aluminum production.

Eirik Hagen

Eirik Hagen is discipline manager for the Materials Group in Primary Metal Technology at Hydro Aluminium. He received a Ph.D. in inorganic chemistry from the Norwegian University of Science and Engineering (NTNU) in 2000 within the field of ceramic side lining materials. Hagen has since then gained experience from various R&D projects, from first Norsk Hydro, and later Hydro Aluminium. He has been involved in material testing and development from lab to industrial scale, especially lining materials for aluminum electrolysis. His primary occupation today is developing material solutions for energy efficient and high productivity electrolysis cells.

Christian Schøning

Christian Schøning is senior advisor at the research team Electrolysis and High Temperature Materials at SINTEF Materials and Chemistry. He has more than 35 years of experience as a research scientist within the fields of refractory and insulation materials used in anode baking furnaces, cast house furnaces, and aluminium electrolysis cells. He is leader of the ALILAB consortium in Norway, (a collaboration of all the Norwegian aluminium plants) to test and establish new test methods for refractories. He has regularly given lectures and seminars on refractories for the Norwegian aluminium industry since 1986 and has published around 25 scientific papers.

Egil Skybakmoen

Egil Skybakmoen is currently research manager for the research team Electrolysis and High Temperature Materials at SINTEF Materials and Chemistry. He has more than 30 years of experience within several primary aluminum research topics. He has published around 50 scientific papers and around 30 papers within TMS as the main author and co-author. His special expertise within refractories is nitride-bonded SiC sidelining materials, where he has six scientific papers and numerous clients for testing and analysis of the different commercial materials existing in the world market. He has also been involved in research activities regarding carbon cathode wear mechanism.

Asbjørn Solheim

Asbjørn Solheim is the chief scientist on the research team Electrolysis and High Temperature Materials at SINTEF Materials and Chemistry. He has nearly 40 years of experience in the industry. His main research interests are molten salts, electrochemistry, thermodynamics, and transport processes applied in the field of primary aluminium production—in particular, bath chemistry and sideledge dynamics. He is author and co-author of 115 papers, including more than 60 papers presented at TMS conferences through 2016.

Zhaohui Wang

Zhaohui Wang is a research scientist on the research team Electrolysis and High Temperature Materials at SINTEF Materials and Chemistry and adjunct associated professor at department of materials science and engineering at Norwegian University of Science and Engineering (NTNU). She received her Ph.D. from NTNU 2010 regarding the degradation mechanism of nitride-bonded SiC materials used in aluminum electrolysis cells. Her special interest is within refractories, nitride-bonded SiC linings, and carbon cathode materials for aluminium production. Her research area covers the range of material characterization, electrolysis, thermodynamics, and atomistic modelling

REGISTRATION

Registration for this professional development event is available through the TMS 2017 Annual Meeting & Exhibition Registration Form. Please note that registration for the full TMS Annual Meeting & Exhibition is not required to attend a professional development event. Course materials are included in the registration fee and will be distributed as digital download prior to or after the conclusion of the program as provided by instructors.

Registration Fees:

On or Before January 20, 2017

After January 20, 2017

|

| |

|