Mathematical modeling is an important

tool for the development of materials

and processes for making them. Modeling

electrochemical processes for smelting

or plating metals presents several

particularly difficult challenges. Boundary

conditions are nonlinear and timedependent,

often because phenomena at

multiple length scales are inextricably

linked. For example, the Angstrom-scale

double layer gives rise to nonlinear voltage-current behavior, which is a boundary

condition for macroscopic models.

And development of micrometer-scale

dendrites dramatically changes both the

product form and the apparent resistance

at the interface; chemical additives can

suppress dendrites and produce superconformal

filling of very rough surfaces.

This paper gives an overview of modeling

approaches at all length scales from

Angstroms to meters, including both mean

field and atomistic approaches.

INTRODUCTION

Electrometallurgy dominates aluminum

extraction, is significant in magnesium

production, and has wide applications

in the refi ning of copper and many

other metals. In many metallothermic

reduction processes, electron transfer

provides a pathway for reduction and

oxidation reactions to happen at different

locations, providing more reaction area

and improving kinetics. On a much smaller scale, integrated circuit copper

metallization uses electroplating, not

evaporation or chemical vapor deposition,

because of its superconformal filling

ability. All of these processes share the

use of electrons to change the oxidation

state of ions and atoms.

Engineers designing these processes

face a wide variety of challenges. At the

largest scales, uneven current distribution

leads to uneven plating rate or uneven

heating of cell components. At smaller

scales, the deposit often forms dendrites,

which are usually a poor product and can

even stretch across the electrolyte and

create a short circuit. In the Hall cell,

aluminum forms streamers which are the

liquid equivalent of dendrites; these break

into tiny droplets or “metal fog” that

increase the electronic conductivity of

the electrolyte, reducing cell efficiency.

Electrochemistry also creates significant opportunities. Additives can eliminate

dendrites and help to fill rough

surfaces and deep trenches more uniformly

than with other thin film techniques.

Alternating current with a carefully

chosen waveform can create a

powder or flake product. And on a small

scale a carefully controlled short circuit

can be used as a switch.

As with any engineering pursuit,

mathematical models can facilitate the

design of electrochemical cells around

these challenges and opportunities. Such

models fall into three categories based

roughly on length scale (Figure 1). Macroscopic

models predict current densities

and plating rates over centimeter to meter

lengths. Meso-scale models predict

interface stability and the shape of dendrites

or streamers at submicrometer to

millimeter scales; some also resolve

nanometer-scale double layer phenomena

and estimate non-ohmic charge transfer

resistance. And finally, atomistic models

explicitly track the motion of individual

atoms, sometimes even their bonding

electrons, to study fundamental mechanisms

of bonding and charge transfer at

interfaces.

The following sections that describe

these models and their applications will

focus on processes for making metals,

leaving aside topics such as batteries and

corrosion.

MACROSCOPIC MODELS

The purpose of macroscopic models

is to help engineers lay out electrochemical

cells on centimeter or larger

scales in order to achieve a desired plating

rate profile. They calculate the electrical

potential, concentration, and

sometimes electrolyte flow velocity

fields, which determine the ionic current

from anode to cathode. The current is

driven by the applied voltage and limited

by resistance to ionic conduction throughout

the electrolyte, resistance due to slow

mass transfer (if applicable), and nonohmic

(nonlinear) resistance to electrochemical

reaction kinetics at the cathode

and anode surfaces. Generally the macroscopic

models assume smooth electrode

surfaces, ignoring any roughening

due to uneven plating.

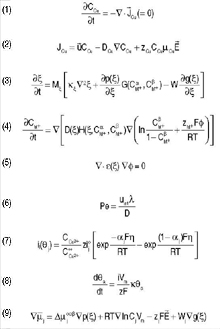

The Nernst–Planck equations1 describe

transport of ions in the electrolyte (e.g.,

of Cu2+ ions in aqueous solution for

copper plating). Equation 1 shows the

rate of change of local copper concentration

CCu due to its flux.

Many electrochemical cells rapidly

establish a steady state where the local

concentration changes very slowly, thus

∂CCu/∂t = 0. In the most general case,

the flux has terms for diffusion with

diffusivity DCu, convection fluid flow due

to velocity field ū, and electromigration

due to electric field Ē

as shown in Equation 2, where zCu is the ionic charge (two

for Cu2+) and μCu is mobility given by

the Einstein relation DCu = (RT/F )μCu.

R is the gas constant, T is the absolute

temperature, and F is Faraday’s constant.

Put in words, flux follows the flow, goes

down the concentration gradient (from

high to low concentration), and (positive)

cations follow the electric field while

anions go the opposite way. In many plating and smelting operations, electromigration

is much faster than diffusion

and flow mixes the electrolyte rapidly,

such that the electromigration term

dominates the flux. Generally, macroscale

simulations solve Equation 2, along

with conservation equations for other

ions and an equation for conservation of

charge, to compute the distributions of

concentrations and electrical potential.

Figure 2 shows the result of a calculation

which estimates the distribution of

plating current driven by the imposed

potential based on electrolyte resistance

(using electromigration flux alone) and

charge transfer resistance at the electrode

surfaces. A process engineer can use this

model to position the electrodes in order

to make the current density relatively

uniform, and to determine at what total

current the highest local plating current

density might lead to a rough deposit.

The paper by U. Pal and A. Powell in

this issue gives another example of this

type of model. In the magnesium oxide

reduction cell described there, the design

objectives are to minimize overall cell

resistance and to avoid high local current

density through the solid oxide membrane

anodes in order to prevent excessive

local heating. Again, the model

provides guidance for electrode placement

that best meets these criteria.

These models are thus very useful

design tools for estimating plating rates

when the deposit is smooth. However,

in many cases, particularly with additives,

it is hard to know a priori when

the deposit will be smooth or rough. And

in some cases, one wants a rough deposit

and needs to know how the process

parameters determine the shape of dendrites

or whether they break off (e.g., for

making powder or flake product). For

these cases, meso-scale models are

necessary.

MESOSCALE MODELS

Models at the micrometer to millimeter

scale simulate shape and topology

dynamics at the deposit surface. Such

models often assume simplified charge

transfer resistance at the interface, such

as first-order (linear, ohmic) kinetics or,

at high temperature, negligible charge

transfer resistance.

Typically, boundary conditions apply

at the phase interface that depend on the

shape and local environment of that interface. These boundary conditions

cause the interface to evolve by deposition

or dissolution, which changes its

shape and local environment, which

again causes it to evolve, forming structures

such as solid dendrites or liquid

streamers. Such complicated morphologies

present significant challenges for

traditional sharp interface methods as

sections of the interface either impinge

or break off. Complex algorithms are

needed to determine whether, and where,

to insert or delete mesh points along the

changing interface.

The class of “diffuse interface” methods

overcomes this topological difficulty

by not attempting to explicitly track the

position of the interface. Rather, they

introduce a continuously varying field.

Contours on this field with a particular

value (sometimes called “level sets”) are

taken to represent the position of the

interface. Changes in topology (impingement,

voids, nucleation of new phases)

present no difficulty for these methods

because the changing contour plays no

role in the calculation; it is simply a

visualization tool.

There are two broad classes of diffuse

interface techniques for electrochemical

modeling. Phase field models begin with

fundamental thermodynamic and kinetic

principles and derive governing equations

that may or may not be directly

compared to their empirical counterparts,

but which often predict the rich behavior

observed in experiments. Level set

models start with known empirical relationships

and model the evolution of

complex morphologies.

Transport-Limited Phase Field Models

Y. Shibuta et al.4,5 and A. Powell et al.6–12 developed phase field models for

electrochemical processes with negligible

interface effects on current flow.

These models use Laplace’s equation

(Shibuta) or continuity of current density

(Powell) to calculate the electrostatic

potential. The gradient of the potential,

which is the electric field, then drives

the metal ions in the electrolyte phase

and the electronic current in the metal

phase.

At high temperature or in situations

with slowly flowing or stagnant electrolytes,

charge transfer at the interface

is much faster than mass transfer to the interface. Under these mass transfer-limited

conditions, models may assume that

charge transfer resistance at the interface

is negligible. When charge accumulation

at interfaces is faster than other changes

affecting the electric field (e.g., not highfrequency

alternating current), models

may further assume that net charge at

the interface is quasi-steady-state, so

normal charge density is the same on

both sides.

Shibuta4 begins with a Ginzburg–Landau free energy functional that

includes the electrostatic potential. The

phase field order parameter ξ ranges from 1 in the electrode (α) to 0 in the electrolyte (Β). The model assumes that the electrode is an ideal metal M and the electrolyte is an ideal sulfide M2A or MA. This is thus a binary M–A system. For simplicity, the model uses a dilute-solution approximation in the electrode and an ideal-solution approximation in the electrolyte phase. It also assumes that the molar volumes of M and A are the same. Hence, the free-energy density is expressed using CM+, the mole fraction of M, and the phase field parameter ξ. Based on the KKS model13 with the above conditions, the governing equations are Equations 3 and 44 where Mξ is the mobility of the phase field, ρ(ξ) characterizes the energy of gradients in the phase field, ρ(ξ) is an interpolation function, g(ξ) is a double well potential energy function, W is the height of that double well, G(CaM+ ,CΒM+) is the thermodynamic driving force for M+ M+ phase transformation, and H(ξ, CaM+,CΒM+) is a thermodynamic factor relating diffusivity to M+ M+ mobility. The superscript α and Β denote the value of CM+ projected into the bulk electrode or electrolyte phase, respectively.

In addition to Equations 3 and 4,

Laplace’s Equation 5 with an applied

voltage at the boundary is solved for the

distribution of the electrostatic potential.

Shibuta et al. use this model to simulate

two processes:

- Bridge formation in a nanometer

scale switch

- Electrochemical deposition of

metals from an unsupported electrolyte

solution

K. Terabe et al.14 and T. Sakamoto et al.15 developed nanometer-scale switches

in ionic/electronic conductor systems such as Cu/CuS and Ag/Ag2S. They

operate by electrochemically depositing

a metal bridge through the sulfide.

However, experiments have shown that

these switches have limited lifetimes,

and the reason for this is still unknown.

A numerical simulation may help with

their development.

Figure 3a shows snapshots of the

electrolyte concentration during bridge

formation. The voltage signal at the right

boundary amplified the disturbance of the

interface caused by noise. Then, a cusp

made by the disturbance of the interface

rapidly grew by plating toward the right

edge where voltage was largest, and

eventually reached the right boundary.

The narrowest part of the bridge was

against the bulk electrode. Next, the

voltage reversed polarity for 23.5 μs.

Figure 3b shows snapshots of the bridge

disappearance process in response to the

positive applied voltage. The electrode

cusp dissolved from the right side and the

bridge structure was separated. Though

this calculation used parameters for ideal

metal/sulfide M/M2A, it can provide

insight into the bridge formation process

to guide experiments.

The next application was electrodeposition.5 Plating morphologies come

in many varieties, including homogeneous,

dendritic, fractal, open-ramified,

finger-like, and other complex structures

depending on applied voltage and electrolyte

concentration.16–20 Others have used diffusion-limited aggregation20 and mean-field lattice gas21,22 approaches to study these phenomena. Shibuta et al.5,23 applied a phase field model to analyze

the morphological transition of electrodeposits.

Figure 4 shows deposit morphologies

calculated by this method as a function

of the applied voltage and equilibrium

mole fraction of M+ in the electrolyte. For

a given applied voltage, deposits tended

to be dendritic at higher concentrations.

Growth velocity of the deposits was

proportional to the applied voltage at

each concentration. These parameters

need to be revised23 for real materials such as Cu/CuSO4 or Zn/ZnSO4 in order to make them physically meaningful.

The models of Powell and W. Pongsaksawad

use a very similar methodology

toward several ends. First, they model

migration and breakdown of an FeO

layer in iron under an electric field in

three dimensions, as shown in Figure 5.

The perturbation on the anode shrinks

because dissolution is faster there,

making the anode unconditionally stable,

whereas the perturbation on the cathode

grows because plating is faster there.

Second, they use numerical simulations

to extend traditional linear stability

analysis of electrodeposition. Stability of

a sinusoidal perturbation of wavelength λ is determined by the Péclet number, which is given by Equation 6. This indicates that the surface is more likely to

roughen at wavelength λ if the deposit is growing fast (large uint plating velocity) and ion diffusivity D is small. The linear stability theory by Barkey24 assumes

that electrodes are infinitely far apart

and have perfect conductivity relative to

the electrolyte, and that the interface is

perfectly sharp. Under these conditions,

the interface is unstable when the Péclet

number is above a critical value of 0.116.

This gives the smallest wavelength λ which will grow for a given plating rate uint and diffusivity D.

Pongsaksawad and Powell extend this

theory by calculating the critical Péclet

number of a solid cathode as a function of

interface thickness, electrode/electrolyte

conductivity ratio, and electrode separation/

wavelength ratio. They also model a

fully liquid system, like liquid aluminum

electrolysis in the Hall cell, and show that

at low viscosity, flow provides another

mechanism to stabilize the interface.

Finally, they extend the model to a

ternary system. This model can capture

electronically mediated reactions, such

as metallothermic reduction. The simulation

shown in Figure 6 illustrates the

reaction between titanium dichloride

and magnesium to produce titanium

and magnesium chloride. In this simulation,

electrical potential is low at the Mg-MgCl2 interface where electrons

are produced and high at the Ti-TiCl2 interface where they are consumed.

CEAC

In the last decade, the “Damascene”

process of electrodepositing copper25

has supplanted evaporated aluminum

for forming the conducting pathways

between the individual semiconductor

devices of integrated circuits. With an

appropriate combination of additives

(accelerators, suppressors, and levelers),

electrodeposited metals can “superfill”

the small (tens of nanometers), high

aspect ratio features found in modern

integrated circuits without forming voids

or seams.

Although traditional leveling models

were initially applied to this process,

they failed to account for the unique

features of bottom-up superfill that make

Damascene viable for this application.

The process works because the metal

is deposited superconformally, filling

from the bottom of a feature faster

than on the sides or the surface of the

wafer, to such a degree that a bump

actually forms over the top of a trench

or via (known as momentum plating).

The curvature enhanced accelerator

coverage (CEAC) mechanism has been proposed26–29 to explain the phenomenon

of electrodeposited superfill. The essence

of the model is that when a suppressor,

such as polyethylene glycol (PEG), is

displaced by an accelerating surfactant such as SPS (Na2(S(CH2)3SO3)2), faster deposition occurs in regions of higher

accelerant coverage and that an advancing

concave surface will tend to concentrate

this accelerant while an advancing

convex surface will tend to dilute it.

The velocity of the growing interface

is directly related to the total current

passing through it, which is the sum of

the partial currents ij mediated by each additive j. Each ij is assumed to depend on the applied overpotential π and the additive surface concentration Θj through a relation like Equation 7, commonly called the Butler–Volmer equation. i°j = i°(Θj) is the exchange current and αj = α(Θj) characterizes the symmetry of the forward and reverse reactions, insert C is the concentration of cupric ions at the electrode surface and CCU2+ is the cupric concentration in the far-field. In

its simplest form, the conservation for

the accelerant a is governed by Equation

8, where the right-hand side is the key to

the mechanism, with concave curvature κ

leading to increasing surface coverage of

accelerant (inducing even faster growth

of the concave surface) and convex κ

leading to decreasing surface coverage.

The CEAC model has also been extended

to treat surface diffusion, adsorption, and

finite additive consumption.

The exchange current i° and the reaction symmetry α are determined

by fitting voltammetric and chronoamperometric

experiments performed on

planar electrodes. These parameters are

then used, without further adjustment,

when modeling filling of features of

different aspect ratios. The electrode

surface is advanced, using the level set

technique, in accordance with the current

passed in Equation 7. This model

has enjoyed considerable success in

predicting desirable superfill versus void

and seam formation in the electroplating

of copper, as illustrated in Figure 7. The

same mechanism has also been found to

describe the electrodeposition of silver

and gold, as well as the chemical vapor

deposition of copper.30

Modeling the Double Layer

When transport in the electrolyte

does not control deposition kinetics,

phenomena in the double layer create

non-ohmic (nonlinear) charge transfer

kinetics. G.M. Gouy31 and D. Chapman32 undertook the first attempt to model the

double layer. They treated the electrode

as an impenetrable boundary with some

imposed potential at its surface and

assumed that ions in the electrolyte obey

a Boltzmann distribution and that the

electrostatic potential was coupled to

the distribution of charges via Poisson’s

equation (Ñ • ηÑφ = ρ, where ρ is the local charge density). The result was a

prediction for the distribution of ions

in the electrolyte, the decay length of

the electrostatic potential, and relationships

between the applied potential and

the surface energy of the electrode, the

charge on the surface of the electrode,

and the differential capacitance of the

charged layers. It is interesting to note

that the Gouy and Chapman treatments

of the electrochemical interface predate

the more widely known Debye–Hückel33 model of charged interfaces by a

decade.

One weakness of the Gouy–Chapman

model, corrected by O. Stern,34 was that

they assumed ions to be infinitesimal

points, allowing them to pack without

constraint near the electrode surface.

Among other things, this caused the

differential capacitance to diverge to

infinity as the imposed surface potential

(or surface charge) was increased.

By accounting for the finite size of the

ions, Stern showed that the differential

capacitance could be considered as two

capacitors in series, one as predicted by

Gouy–Chapman at low biases and another

of constant capacitance that dominates

at high biases, when ions at the surface

reach their packing limit.

Although the Gouy–Chapman–Stern

(GCS) model captures the qualitative

characteristics of the double layer, it

does not account for many of the details

of real electrochemical interfaces. This

has motivated the development of more

sophisticated computational models

similar to GCS, but which capture more

of the details observed in experimental

studies.

Recent density functional treatments,

such as those of Z. Tang et al.,35 have

expanded on the essential elements of

the GCS model and demonstrated rich

electrocapillary behavior reminiscent of

experimental measurements. Like GCS,

these density functional models cannot

treat electroplating or electrodissolution

because the electrode is just a simple

abstraction provided as a boundary condition

to the model.

J.E. Guyer et al.36,37 noted the many

analogies between electrodeposition

and solidification, where the phase

field method has enjoyed considerable

success, and developed a phase

field treatment of the electrochemical

interface. This treatment considered the

same basic physics as the GCS and Tang

models, but also allowed for the plating

or dissolution of the electrode. They

considered four components: cations,

anions, solvent, and electrons. All species

had the same molar volume, except

electrons were assumed to have no molar

volume, allowing them to move freely in

the electrode without having to displace

other species. Although an inert electrochemical

interface could be modeled

with three components in this formalism,

four are necessary to describe plating or

dissolution. All species were assumed

to obey ideal solution thermodynamics

(equivalent to the Boltzmann distribution

assumed in GCS). They included

the electrostatic contribution to the total

free energy and showed that the phase

field gradient energy coefficient and

the dielectric constant are completely

analogous, one penalizing gradients in

the phase field and the other penalizing

gradients in the electrostatic potential.

They did not similarly penalize gradients

in concentration.

The simplest set of assumptions was

made, consistent with conserving each

species and minimizing free energy, to

obtain the governing equations for the

model. In the absence of variations in the dielectric constant, the treatment of

the phase field is identical to that used

by Shibuta et al.4,5 and by Powell et al.6–12 Diffusion equations were obtained in the manner of Equation 1, with fluxes defined by  for electrons and for electrons and  for all species other than electrons and species N (chosen arbitrarily). They related the mobilities Mj to the diffusivities Dj and defined gradients of the electrochemical potential of species j by Equation 9. for all species other than electrons and species N (chosen arbitrarily). They related the mobilities Mj to the diffusivities Dj and defined gradients of the electrochemical potential of species j by Equation 9.

For each component j, Wj is the energy barrier of the activated state and ÑμjΒ is the standard chemical potential difference between the electrode and electrolyte. Vm is the molar volume. ÑμjΒ depends on

the standard state bulk concentrations in

each phase and on the Galvani potential Ñφ° (the difference between the internal

potential or work function of the electrode

and that of the electrolyte). Although

really a property of the electrode material

and electrolyte chemistry, the Galvani

potential is an adjustable parameter in

this model that dramatically affects the

structure of the double layer.

The model solves the phase field and

diffusion equations in conjunction with

Poisson’s equation. The fundamental

difference from GCS or the Tang model

is that the same set of equations govern

both the electrolyte and the electrode, the

difference being that Guyer et al. chose

thermodynamic parameters to favor an

electrode rich in cations and electrons and

an electrolyte rich in solvent, cations, and

anions. They consider both a charge-free

solvent as a simple model of aqueous

solutions (while ignoring the important

effects of polar solvent molecules) and a

charged solvent system as a simple model

of molten salts.

When studying electrode-electrolyte

interfaces at open circuit (in equilibrium),

Guyer et al. found that sweeping the

Galvani potential (effectively changing

the electrode material) produced changes

in surface energy, surface charge, and

differential capacitance that were qualitatively

consistent with the electrocapillary

theory for sweeping the voltage applied to an inert electrode. [VIEW ANIMATION] As

seen in Figure 8, however,

the detailed predictions are

markedly different from the GCS models

but bear a striking resemblance to the

behavior observed in experimental studies of solid metal electrodes.

On examining moving interfaces (plating

or dissolution), Guyer et al. showed

that the model yields expected behavior such as limiting current and

alloy plating. [VIEW ANIMATION] Most dynamic models

of electrodeposition, including

the level set treatment described, assume

that the Butler–Volmer equation governs

the relationship between current and overpotential

and use it to evolve the shape of

the interface. This model assumed a linear

relationship between phase evolution

rate and driving force, but gave rise to a

non-linear relationship between current

and overpotential, consistent with the

empirical Butler –Volmer relation. This

is the power of phase field: simple physical

relationships, applied rigorously, give

rise to complex phenomena, but without

having to hypothesize complex origins.

Although the model is not intrinsically

limited to one dimension, higher

dimensions have proven computationally

intractable without choosing a number

of unphysical parameters. Reasons for

this include very small Debye length

(separation between charged planes in the

double layer) requiring very fine spatial

resolution, and abrupt changes in concentration

of many orders of magnitude in

order to capture an intuitively acceptable

approximation of a real metal-electrolyte

interface (i.e., no water in the electrode,

no free electrons in the water). Although

not considered in this treatment, the

anisotropy of adsorption behavior on

different crystallographic surfaces can

be incorporated in the thermodynamic

derivation of a phase field model.

The phase field treatments of Powell et

al. and Shibuta et al. avoid these difficulties

(at the loss of some details about the

interface) by replacing Poisson’s equation

with Laplace’s and by modeling a different

set of concentration variables that do

not experience such extreme changes in

magnitude. It remains to be seen if the

approaches can be successfully merged

to model larger systems, in higher dimensions,

while retaining the electrocapillary

phenomena of the double layer.

Summary

Meso-scale models provide important

insights into physical phenomena at the

scale of dendrites and microfabricated

features. They are thus useful as design tools for engineers seeking to avoid or

utilize spontaneous roughness formed

by electrodeposition. Continuum theories

can even shed new light on nanometerscale

phenomena such as the electrochemical

double layer. However, many of

these models require parameters that are

very difficult to measure, such as homogeneous

free energy at compositions

which are not homogeneous, and bonding

energies. For these parameters and

fundamental understanding at smaller

scales, we turn to atomistic models.

ATOMISTIC MODELS

Atomistic and first-principles methods

help provide insight into processes that

occur on the atomic or subatomic scale

in order to better understand fundamental

processes, aid in the design of materials,

and estimate parameters for use in

other models. For example, they can be

used to examine the formation of adlayers

at interfaces during electrodeposition

and properties of the electrical double

layer that forms due to charge separation,

and they can be used to calculate materials

parameters such as the binding energy

of an atom on a surface. These methods

provide information about atomic- and

electronic-scale phenomena that is

unavailable from models on larger length

and time scales. However, they can also

be limited by small sizes, short times,

and the dependence of results on the

physical approximations used in the

calculations. The computational methods

of interest include molecular simulation techniques such as Monte-Carlo (MC)

and molecular dynamics (MD), and

electronic structure, or first-principles,

methods.

Monte-Carlo simulations are grounded

in a statistical-mechanical treatment of

particles where system evolution is based

on how random moves (such as changes

in atomic coordinates) affect the state of

the system. Equilibrium (or static) MC

methods cannot be associated with real

time, but kinetic (or dynamic) MC methods

use attempt frequencies of moves to

relate the simulation evolution to physical

time.39 Classical MD techniques solve

Newton’s equations of motion to model

the evolution of particles (usually atoms)

under conditions such as constant temperature.40 Since MC moves are not tied

to particle trajectories, it is often possible

to treat larger systems for longer periods

of time than can be achieved with MD,

though the two techniques can be used

in parallel or in series for some problems.

First-principles (or ab-initio) methods

use quantum-mechanical descriptions of

atoms to calculate materials properties

and examine chemical reactions (e.g.,

Reference 41). First-principles methods

provide very detailed information about

individual atoms, but the computational

cost is high, leading to small system sizes.

This section is intended to provide

examples of interesting work and is not

exhaustive.

To understand the origins of ordered

overlayers and surface phase transitions,

first-principles and atomistic simulations

have been used in combination with

experimental methods such as cyclicvoltammetry

and chronocoulometry.

These systems can be viewed as model

systems for the interfaces between electrodes

and aqueous electrolytes. A review

of the behavior and importance of ordered

anion adlayers on metal electrode surfaces

can be found in Reference 42. Using

kinetic MC and equilibrium MC, the

origins of ordered overlayers and surface

phase transitions have been examined.

For example, N. Garcia-Araez et al.

recently compared dynamic MC simulations

and mean-field approximations with

experimental results to examine the

competitive adsorption of hydrogen and

bromine on Pt(100), finding that the MC

results could adequately model the

system, but that the mean-field approach

could not.43 S. Frank and P.A. Rikvold

studied how lateral adsorbate diffusion

affects first-order phase transitions in a

two-dimensional Ising lattice gas model

with attractive nearest-neighbor interactions.44 Some models have coupled MC

simulations with continuum models in

order to bridge size and time scales such

as in the study of a potential step test in

a copper sulfate bath to examine electrodeposition

and electrodissolution of

copper at an electrode.45 Materials parameters

used to parameterize the interatomic

interactions, such as binding energies

between atoms, have been calculated with

ab-initio methods and often compared

with experimental methods.

While the double layer is a phenomenon

of great interest, continuum models

provide little insight into the atomic-scale

mechanisms at interfaces such as the

orientation of the dipolar water molecules

and the effect of ions on interfacial structure.

Many theoretical and simulation

(including MC and MD) studies have

examined the double layer (e.g., References

46–50). Recently P. Taboada-Serrano

et al. examined mixtures of symmetric

and asymmetric electrolytes near

discretely charged planar surfaces using

MC methods to examine the effects of

surface charge distribution and asymmetry

in charge and size on the structure

of the double layer, finding that the thickness

and ionic distribution in the double

layer were strongly affected by them.51

C. Hartnig and M.T.M. Koper used MD

to simulate ion transfer reactions of

chlorine in water at metal electrodes,

where they found that solvent reorganization

related to the electron transfer and

ion transfer behaved differently—the first

was dominated by long-range electrostatics

while the latter was influenced by

shorter-range solvent effects.52

As mentioned, ab-initio methods have

been used to calculate materials parameters

(cohesive energies, preferred binding

sites, etc.) and to examine electrochemical

reactions. The information

gained from these methods can then be

used to inform higher-level simulations

and models for a more complete understanding

of electrochemical interfaces.

For example, Z.C. Wang et al.53 have been

studying the electrical properties of the

Ag/Ag2S/Ag junction nanometer-scale

switch mentioned previously. They used

density functional theory and a nonequilibrium

Green’s function method to

calculate current-voltage characteristics,

as shown in Figure 9. A. Migani et al.

studied halogens on low-index surfaces

of transition metals, calculating atomic

structure, adsorption energies, vibrational

frequencies, and net charges.54 While the

halogen study was performed in vacuum,

with results to be extrapolated to aqueous

solutions, C. Taylor et al. studied electrochemical

reactions at the Ni(111)/H2O

interface to determine interfacial structure

and when water and its activation

products are stable.55 Further review of

work related to aqueous/metal interfaces

can be found in Reference 56.

Atomic- and molecular-scale methods

have become much more useful for both

the design of materials and the fundamental

understanding of materials

behavior. Coupled with models on higher

length scales and compared with experimental

results, they can provide a more

complete picture of electrochemical

behavior.

CONCLUSION

Electrochemistry plays several key

roles in metallurgy, including processes

for extracting and fabricating metals at

all length scales. In terms of extraction,

it will likely grow in importance as the

price of carbon emissions tips the balance

from carbothermic to electrochemical

processes in some applications. Models

such as those described in this paper will

play an increasing role in the rapid design

and development of these processes.

Furthermore, these models are useful

for studying corrosion and designing a

wide range of electrochemical devices.

Batteries come to mind here, as do hybrid

photo-electric hydrolysis devices for

generating hydrogen and electrochemical

solar cells. For all of these applications,

models can provide understanding and

predict behavior to inform intelligent

design of new devices and products.

ACKNOWLEDGEMENTS

Adam Powell would like to thank Donald Sadoway and James Warren for discussions that influenced this work, and much of Pongsaksawad and Powell’s meso-scale work described here was supported by the National Science Foundation (Award DMI-0457381) and a Royal Thai Government Fellowship. Yasushi Shibuta would like to thank Prof. T. Suzuki, Prof. S. Yamaguchi, and Mr. Y. Okajima (The University of Tokyo) for their help in modeling and calculations, and MEXT, Japan for financial support of the Grant-in-Aid for Scientific Research on Priority Area “Nanoionics (439).” Chandler A. Becker would like to thank the National Research Council-National Academy of Sciences Postdoctoral Research Associate program for support. We are grateful to Tom Moffat and Daniel Wheeler for many helpful comments on this manuscript.

REFERENCES

1. Max Planck, “Ueber die Erregung von Electricit¨at und Wärme in Electrolyten,” Ann. Physik. u. Chem., 39 (1890), p. 161.

2. Elsyca, www.elsyca.com/.

3. The identification of any commercial product or trade name does not imply endorsement or recommendation by the National Institute of Standards and Technology.

4. Y. Shibuta, Y. Okajima, and T. Suzuk, “A Phase-Field Simulation of Bridge Formation Process in a Nanometer-Scale Switch,” Scripta Materialia, 55 (2006), pp. 1095–1098.

5. Y. Okajima, Y. Shibuta, and T. Suzuki, “Phase-Field Simulation of an Electrodeposition Process,” Electrochemistry and Thermodynamics on Materials Processing for Sustainable Production: Masuko Symposium, ed. Shu Yamaguchi (Tokyo: The University of Tokyo, 2006), pp. 829–834.

6. David Dussault, “A Diffuse Interface Model of Transport Limited Electrochemistry in Two-Phase Fluid Systems with Application to Steelmaking” (S.M. Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, January 2002).

7. David Dussault and Adam C. Powell, “Phase Field Modeling of Electrolysis in a Slag or Molten Salt,” Proc. Mills Symp. (London: The Institute of Materials, 2002), pp. 359–371.

8. Adam C. Powell and David Dussault, “Detailed Mathematical Modeling of Liquid Metal Streamer Formation and Breakup,” Metallurgical and Materials Processing Principles and Technologies (Yazawa International Symposium)–Vol. 3: Aqueous and Electrochemical Processing, ed. F. Kongoli et al. (Warrendale, PA: TMS, 2003), pp. 235–250.

9. Wanida Pongsaksawad, Numerical Modeling of Interface Dynamics and Transport Phenomena in Transport-Limited Electrolysis Processes (Ph.D. Thesis, Massachusetts Institute of Technology, Department of Materials Science and Engineering, May 2006).

10. Adam C. Powell, Wanida Pongsaksawad, and Uday B. Pal, “Phase Field Modeling of Phase Boundary Shape and Topology Changes Due to Electrochemical Reactions in Solid and Liquid Systems,” Advanced Processing of Metals and Materials Vol. 3: Thermo and Physicochemical Principles: Special Materials; Aqueous and Electrochemical Processing (Warrendale, PA: TMS, 2006), pp. 623–640.

11. Adam C. Powell, Wanida Pongsaksawad, and Uday B. Pal, “Phase Field Modeling of Phase Boundary Shape and Topology Changes Due to Electrochemical Reactions in Solid and Liquid Systems,” Electrochemistry and Thermodynamics on Materials Processing for Sustainable Production: Masuko Symposium, ed. Shu Yamaguchi (Tokyo: University of Tokyo, November 2006), pp. 793–814.

12. Wanida Pongsaksawad, Adam C. Powell, and David Dussault, “Phase Field Modeling of Transport-Limited Electrolysis in Solid and Liquid States,” J. Echem. Soc., 154 (6) (June 2007).

13. S.G. Kim, W.T. Kim, and T. Suzuki, “Phase-Deld Model for Binary Alloys,” Phys. Rev. E, 60 (6) (1999), pp. 7186–7197.

14. K. Terabe et al., “Formation and Disappearance of a Nanoscale Silver Cluster Realized by Solid Electrochemical Reaction,” J. Appl. Phys., 91 (12) (2002), pp. 10110–10114.

15. T. Sakamoto et al., “Nanometer-Scale Switches Using Copper Sulfide,” Appl. Phys. Lett., 82 (18) (2003), pp. 3032–3034.

16. Y. Sawada, A. Dougherty, and J.P. Gollub, “Dendritic and Fractal Patterns in Electrolytic Metal Deposits,” Phys. Rev. Lett., 56 (12) (1986), pp. 1260–1263.

17. F. Sagues, M.Q. Lopez-Salvans, and J. Claret, “Growth and Forms in Quasi-Two-Dimensional Electrocrystallization,” Physics Reports, 337 (2000), pp. 97–115.

18. G. Gonzalez et al., “Viscosity Effects in Thin-Layer Electrodeposition,” Journal of the Electrochemical Society, 148 (7) (2001), pp. C479–C487.

19. C. Leger, J. Elezgaray, and F. Argoul, “Internal Structure of Dense Electrodeposits,” Phys. Rev. E, 61 (5) (2000), pp. 5452–5463.

20. M. Matsushita et al., “Fractal Structure of Zinc Metal Leaves Grown by Electrodeposition,” Phys. Rev. Lett, 53 (3) (1984), pp. 286–289.

21. J. Elezgaray, C. Leger, and F. Argoul, “Dense Branching Morphology in Electrodeposition Experiments: Characterization and Mean-Field Modeling,” Phys. Rev. Lett., 84 (14) (2000), pp. 3129–3132.

22. M.O. Bernard, M. Plapp, and J.F. Gouyet, “Mean-Field Kinetic Lattice Gas Model of Electrochemical Cells,” Phys. Rev. E, 68 (2003), p. 011604.

23. Y. Shibuta, Y. Okajima, and T. Suzuki, in preparation.

24. D.P. Barkey, R.H. Muller, and C.W. Tobias, “Roughness Development in Metal Electrodeposition: II. Stability Theory,” J. Electrochem. Soc., 136 (1989), pp. 2207–2214.

25. P.C. Andricacos et al., “Damascene Copper Electroplating for Chip Interconnections,” IBM J. Res. Develop., 42 (5) (1998), pp. 567–574.

26. D. Josell et al., “Superconformal Electrodeposition in Submicron Features,” Phys. Rev. Lett., 87 (1) (2001), p. 016102.

27. D. Wheeler, D. Josell, and T.P. Moffat, “Modeling Superconformal Electrodeposition Using the Level Set Method,” J. Electrochem. Soc., 150 (5) (2003), pp. C302–C310.

28. T.P. Moffat, D. Wheeler, and D. Josell, “Superfilling and the Curvature Enhanced Accelerator Coverage Mechanism,” Interface (Winter 2004), pp. 46–52.

29. T.P. Moffat et al., “Superconformal Film Growth: Mechanism and Quantification,” IBM J. Res. Develop., 49 (1) (2005), pp. 19–36.

30. D. Josell, D. Wheeler, and T.P. Moffat, “Superconformal Deposition by Surfactant-Catalyzed Chemical Vapor Deposition,” Electrochemical and Solid State Letters, 5 (3) (2002), pp. C44–C47.

31. G.M. Gouy, “Sur la Constitution de la Charge Électrique à la Surface d’un Électrolyte,” Compt. Rend., 149 (1910), p. 654.

32. David Leonard Chapman, “A Contribution to the Theory of Electrocapillarity,” Phil. Mag., 25 (1913), p. 475.

33. P. Debye and E. Hückel, “Zur Theorie der Elektrolyte I. Gefrierpunktserniedrigung und verwandte Erscheinungen,” Physik. Z., 24 (1923), pp. 185–206.

34. Otto Stern, “Zur Theorie der Elektrolytischen Doppelschicht,”Z. Elektrochem., 30 (1924), p. 508.

35. Zixiang Tang, L.E. Scriven, and H.T. Davis, “A Three-Component Model of the Electrical Double Layer,” J. Chem. Phys., 97 (1992), pp. 494–503.

36. J.E. Guyer et al., “Phase Field Modeling of Electrochemistry I: Equilibrium,” Phys. Rev. E, 69 (2004), p. 021603.

37. J.E. Guyer et al., “Phase Field Modeling of Electrochemistry II: Kinetics,” Phys. Rev. E, 69 (2004), p. 021604.

38. G. Valette, “Double Layer on Silver Single Crystal Electrodes in Contact with Electrolytes Having Anions Which are Slightly Specifically Adsorbed Part II. The (100) Face,” J. Electroanal. Chem., 138 (1982), pp. 37–54.

39. M.E.J. Newman and G.T. Barkema, Monte Carlo Methods in Statistical Physics (Oxford, U.K.: Clarendon Press, 1999).

40. D.C. Rapaport, The Art of Molecular Dynamics Simulation, second edition (Cambridge, U.K.: Cambridge University Press, Cambridge, 2004).

41. D.G. Pettifor, Bonding and Structure of Molecules and Solids (Oxford, U.K.: Clarendon Press, 1995).

42. O.M. Magnussen, “Ordered Anion Adlayers on Metal Electrode Surfaces,” Chem. Rev., 102 (2002), pp. 679–725.

43. N. Garcia-Araez et al., “Competitive Adsorption of Hydrogen and Bromide on Pt(100): Mean-Field Approximation vs. Monte Carlo Simulations,” J. Electroalytical Chem., 588 (2006), pp. 1–14.

44. S. Frank and P.A. Rikvold, “Kinetic Monte Carlo Simulations of Electrodeposition: Crossover from Continuous to Instantaneous Homogeneous Nucleation within Avrami’s Law,” Surf. Sci., 600 (2006), pp. 2470–2487.

45. A. Saedi, “A Study on Mutual Interaction between Atomistic and Macroscopic Phenomena during Electrochemical Processes Using Coupled Finite Difference–Kinetic Monte Carlo Model: Application to Potential Step Test in Simple Copper Sulfate Bath,” J. Electroanalytical Chem., 588 (2006), pp. 267–284.

46. R. Guidelli, “Recent Developments in Models for the Interface between a Metal and an Aqueous Solution,” Electrochimica Acta, 45 (2000), pp. 2317–2338.

47. W.R. Fawcett and T.G. Smagala, “New Developments in the Theory of the Diffuse Double Layer,” Langmuir, 22 (2006), pp. 10635–10642.

48. E. Spohr, “Some Recent Trends in Computer Simulations of Aqueous Double Layers,” Electrochimica Acta, 49 (2003), pp. 23–27.

49. R.R. Netz, “Theoretical Approaches to Charged Surfaces,” J. Phys. -Cond. Matter, 16 (2004), pp. S2353–S2368.

50. M.T.M. Koper, “Combining Experiment and Theory for Understanding Electrocatalysis,” J. Electroanalytical Chem., 574 (2005), pp. 375–386.

51. P. Taboada-Serrano, S. Yiacoumi, and C. Tsouris, “Behavior of Mixtures of Symmetric and Asymmetric Electrolytes Near Discretely Charged Planar Surfaces: A Monte Carlo Study,” J. Chem. Phys., 123 (2005), p. 054703.

52. C. Hartnig and M.T.M. Koper, “Molecular Dynamics Simulation of Solvent Reorganization in Ion Transfer Reactions near a Smooth and Corrugated Surface,” J. Phys. Chem. B, 108 (2004), pp. 3824–3827.

53. Z.C. Wang et al., in preparation.

54. A. Migani and F. Illas, “A Systematic Study of the Structure and Bonding of Halogens on Low-Index Transition Metal Surfaces,” J. Phys. Chem. B, 110 (2006), pp. 11894–11906.

55. C. Taylor, R.G. Kelly, and M. Neurock, “First-Principles Calculations of the Electrochemical Reactions of Water at an Immersed Ni(111)/H2O Interface,” J. Electrochemical Soc., 153 (2006), pp. E207–E214.

56. C.D. Taylor and M. Neurock, “Theoretical Insights into the Structure and Reactivity of the Aqueous/Metal Interface,” Current Opinion in Solid State and Materials Science, 9 (2005), pp. 49–65.

Adam C. Powell IV is managing engineer at Veryst Engineering LLC, 47A Kearney Rd., Needham, MA 02494-2503, USA. Yasushi Shibuta is an assistant professor at The University of Tokyo, 7-3-1 Hongo, Bunkyo-ku, Tokyo 113-8656, Japan. Jonathan Guyer and Chandler A. Becker are materials research engineers at National Institute of Standards of Technology, Gaithersburg, MD 20899, USA. Dr. Powell can be reached at (781) 433-0433, ext. 12; fax (781) 433-0933; e-mail apowell@veryst.com. |