TMS 2016 Course Offerings

12th Annual Lead-Free Solders and Interconnect Technology Workshop

Additive Manufacturing Materials and Processes Workshop

Avizo 3D Analysis Software for Materials Science*

Characterization of Dielectric Materials for Microwave Processing

Effects and Control of Impurities Along the Aluminum Value Chain

Energy Management in the Materials Industry

Explore CES Software Tools for Materials Related Critical Decision-Making in Industry, Research, and Education*

Managing Technical and Financial Risk in a New Technology Project Environment

Multiphysics Materials Simulations Using the Open Source MOOSE Framework

NSF Grant Proposal Writing Workshop

Practical Methods for "In-Plant" Testing of Carbon Anodes Used in Aluminum Smelting

|

| Title | Energy Management in the Materials Industry |

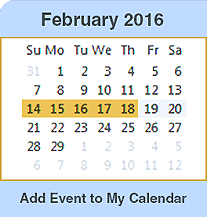

| When | Sunday, February 14, 2016, 8:30 a.m. to 12:30 p.m. (CST) |

| Where | Music City Center |

| Sponsorship | TMS Extraction & Processing Division (EPD), Light Metals Division (LMD), and Energy Committee |

| Presenter | Cynthia Belt, Energy Management Consultant, and Rodrigo Corbari, Vallourec Star |

| Workshop Length | Half-day, morning |

| Flyer |

View / Download View / Download |

"Instructors provided excellent explanation of framework for phase field and finite elements. Very empowering course."

—TMS2015 Course Attendee

SCOPE

Energy management programs provide a structure for continuous improvement to reduce energy costs. Energy efficiency and energy conservation will reduce greenhouse gases, improve the environmental impact of the process, and reduce bottom line costs of the business. Topics include:

- Why implement energy management? Benefits and reasons for an energy management program. What is required to begin an energy program?

- Assigning an energy director, forming an energy team, making an energy policy, and finding resources

- Defining and measuring performance; what should you measure?

- Understanding energy measurements using electricity, natural gas, coal, etc. Understanding critical KPI’s. Setting baselines and benchmarking your plant and processes.

- Analyzing the data and identifying projects.

- Understanding your energy use with data analysis, system analysis, and technical assessments; making a project list; improving the process; and setting goals and creating an action plan

- Controlling the process and evaluating progress.

- Implementing a project action plan; team meetings; tracking your energy performance; and recognizing achievements

In each topic, specific information for the material industry will be highlighted giving a more in-depth look at energy management within the materials industry.

WHO ATTENDS?

This training is directed toward energy managers, engineers, and supervisors working in the materials industry who want to reduce their energy usage. The training is meant to explain both general energy management methods and those areas specific to the metals and materials industry.

TOPICAL OUTLINE

Preliminary Program Agenda

- Introduction

- Why Energy Management?—30 Minutes

- Energy as a Controllable Expense

- Energy markets are changing

- Energy Savings vs. Increased Sales

- Energy vs. Throughput vs. Melt Loss vs. Maintenance Costs

- Environmental Factors

- Energy Management Program

- Steps to Energy Management

- Commit to the Program—15 Minutes

- Energy Manager

- Energy Team

- Energy Policy

- General Resources & Materials Specific Resources

- Define and Measure Performance—60 Minutes

- Data Collection

- Power vs Energy

- Electricity

- Primary Fuels - Natural Gas, Oils, & Coal

- Secondary Fuels & Gases

- KPI’s – Key Performance Indicators

- Goals & Benchmarks

- Equipment Lists

- Analyze Data and Identify Projects—90 Minutes

- Data Analysis

- Energy Intensity

- Project List

- Process Heating

- Waste Heat Recovery

- Furnace Testing

- Technical System Analysis

- Project Methodology

- Control and Evaluate Progress—30 Minutes

- Creating the Action Plan

- Project Methodology

- Track Progress

- Team Meetings & Growing Your Team

- Energy Website

- Recognize Achievements

INSTRUCTORS

Cynthia Belt

Cynthia Belt has led energy management programs at Aleris International, Superior Industries, and Kaiser Aluminum, saving millions of dollars. At TMS, Belt currently serves as vice chair of the Extraction & Processing Division (EPD), is a former chair of the Energy Committee, and has been a member of the Energy Technical Working Group. She is also a member of the Energy Committee for AFS and a member of the project team as ASME that developed "Energy Assessment for Process Heating Systems" and "Guidance for ASME EA-1, Energy Assessment for Process Heating Systems." Belt has published more than 15 papers on energy topics in the materials industry and holds a Six Sigma Black Belt.

Rodrigo Corbari

Rodrigo Corbari is an energy manager at Vallourec Star, a leader in premium steel tubular solutions for the energy markets. He has been working in the steel industry for over seven years. Corbari earned his Ph.D. and master’s degree in materials science and engineering from Carnegie Mellon University, and his B.Sc. from the University of Rio Grande do Sul, Brazil.

REGISTRATION

Registration Fees:

Before January 8, 2016

After January 8, 2016

* Must be a full-time student at an accredited university to register at the student rate. Copy of valid student school identification card must accompany registration form.

|

| BACK TO COURSE LISTING |

|