TMS 2016 Course Offerings

12th Annual Lead-Free Solders and Interconnect Technology Workshop

Additive Manufacturing Materials and Processes Workshop

Avizo 3D Analysis Software for Materials Science*

Characterization of Dielectric Materials for Microwave Processing

Effects and Control of Impurities Along the Aluminum Value Chain

Energy Management in the Materials Industry

Explore CES Software Tools for Materials Related Critical Decision-Making in Industry, Research, and Education*

Managing Technical and Financial Risk in a New Technology Project Environment

Multiphysics Materials Simulations Using the Open Source MOOSE Framework

NSF Grant Proposal Writing Workshop

Practical Methods for "In-Plant" Testing of Carbon Anodes Used in Aluminum Smelting

|

| Title | Effects and Control of Impurities Along the Value Chain |

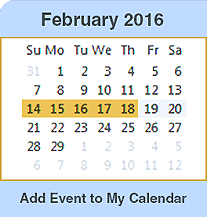

| When | Sunday, February 14, 2016, 8:30 a.m. to 4:30 p.m. (CST) |

| Where | Music City Center |

| Sponsorship | TMS Light Metals Division and Aluminum Committee |

| Presenters | John Grandfield , Grandfield Technology Pty Ltd. and Swinburne University of Technology; Stephen J. Lindsay, Alcoa Inc.; Ray Peterson, Real Alloy; and Pete Forakis, STAS Middle East |

| Workshop Length | Full day |

| Flyer |

View / Download View / Download |

SCOPE

Current changes in raw material purity and increasing product quality standards make understanding of impurity effects along the value chain and impurity control extremely topical. This short course covers sources of impurities in primary and secondary aluminum and their effects along the value chain. Impurities covered include trace elements such as sodium, calcium, nickel, vanadium, etc. Boride treatment for peritectic element removal, hydrogen effects and removal and demagging are included. Inclusion sources and inclusion removal methods are also covered.

WHO ATTENDS?

The course will benefit smelter operators, technical personnel, alloy hardener, and other raw material suppliers. Users and suppliers of melt treatment technology such as degassers and filters will also find the course useful. Researchers interested in investigating impurity effects and developing new impurity removal methods will find the course useful grounding.

TOPICAL OUTLINE

- Impurity sources in primary metal—Steve Lindsay

- Impurity effects in electrolysis and carbon—Steve Lindsay

- Impurity effects on alloy properties—John Grandfield

- Impurity sources and effects secondary metal—Ray Peterson

- Boron treatment—John Grandfield

- Degassing—Ray Peterson

- Sodium removal—Pete Forakis

- Inclusion sources and Metal filtration—John Grandfield

- Demagging—Ray Peterson

INSTRUCTOR BIOS

John Grandfield

John Grandfield is director of Grandfield Technology Pty Ltd., (a consulting and technology firm) and adjunct professor at Swinburne University of Technology in the High Temperature Processing Group. He has a bachelor’s of applied science in Metallurgy (RMIT University), a M.Sc. in mathematical modelling (Monash University), and a Ph.D. in materials science (University of Queensland). Grandfield has 30 years’ experience in light metals research and technology in continuous casting and metal refining and is regularly invited to give training courses, participate in in-house innovation workshops, and conduct R&D program reviews around the world. Grandfield also conducts metals industry analysis on the tungsten and magnesium industries with analysts CM Group. He has four patents, has published two book chapters, more than 50 conference and journal papers and has co-authored a book on DC casting of light metals. He was chair of the TMS Aluminum Committee and editor of Light Metals 2014.

Stephen J. Lindsay

Stephen J. Lindsay currently works as a senior smelting specialist for Alcoa. His background includes numerous technical and managerial capacities at Alcoa’s various smelting locations for more than 35 years. Linsday’s responsibilities include alumina quality, metal purity, electrolysis and bath, and fume control systems. He has published articles in Light Metals, the proceedings of the Australasian Smelting Technology Conferences, and the proceedings of International Alumina Quality Workshops. Lindsay also has served TMS as the editor of Light Metals and subject chair of Reduction Technology, as well as numerous other roles. He was awarded Best Paper for Reduction Technology in 2006 and 2009; has contributed to TMS industrial electrolysis courses and other short courses; and has served as an instructor for graduate programs at the University of New South Wales and the University of Auckland.

Ray Peterson

Ray Peterson is Technology Director for Real Alloy, formerly a division of Aleris International. He has also worked for IMCO Recycling and Reynolds Metals Company during his career. Peterson received his Ph.D. in Metallurgy from the University of Utah in 1984. He has served in many areas of TMS, including as chair of the Aluminum Committee, Light Metals Division Chair, and President in 2009. His professional research interests include molten salt reactions, high temperature thermochemistry, reaction kinetics, heat and energy transport, and molten metal processing.

Pete Forakis

Pete Forakis is the regional director for STAS Middle East. He received his bachelor of engineering in metallurgical engineering from McGill University and his MBA from University of Wollongong. Forakis has previously worked for Emirates Aluminium, Hatch, Rio Tinto Alcan, Noranda, and Alcoa. He was the subject chair for the Cast Shop sessions at the TMS 2015 Annual Meeting & Exhibition and a member of the technical committee of the Australasian Casthouse Technology Conference. He has held positions in operations, engineering, R&D, technical support, and business development.

REGISTRATION

Registration Fees*:

Before January 8, 2016

After January 8, 2016

* Registration fees include lunch.

** Must be a full-time student at an accredited university to register at the student rate. Copy of valid student school identification card must accompany registration form.

|

| BACK TO COURSE LISTING |

|